Overview

Southern Glazer’s Wine and Spirits, the largest wine and spirits distributor in the world, continually seeks innovative solutions to enhance its supply chain operations. Faced with an outdated and outgrown facility in Union City, the company turned to automation to streamline processes, improve efficiency, and prepare for future growth. Through the implementation of advanced automated systems, Southern Glazer’s has set a new standard in the industry, ensuring they meet the evolving needs of their customers and suppliers.

Challenge

Southern Glazers faced significant operational challenges with its outdated and outgrown Union City warehouse. The facility lacked modern technology, limiting the company’s ability to efficiently manage inventory, fulfill orders promptly, and accommodate future growth. The need for a modern, automated facility was clear to meet the company’s long-term business objectives.

Solution

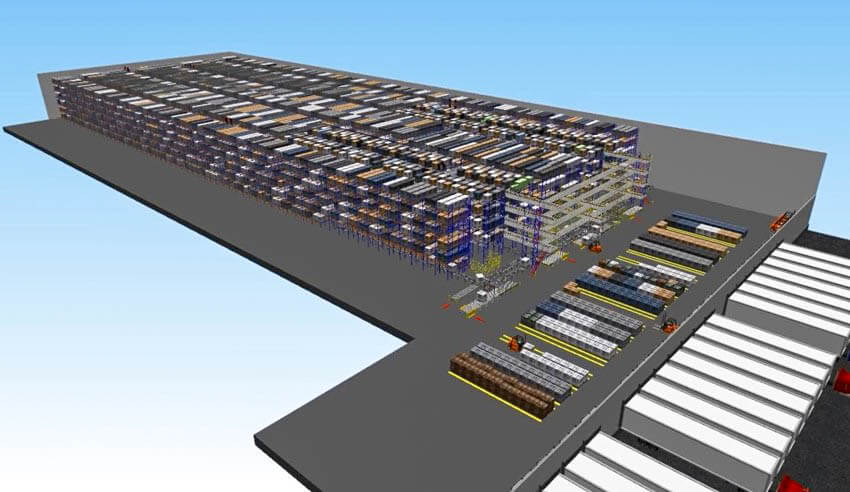

Westfalia Technologies provided a comprehensive solution by designing and implementing a fully automated warehouse system tailored to Southern Glazer’s needs. The new 334,000 square-foot, 55-foot-tall facility is equipped with Westfalia’s high-density automated storage and retrieval system (AS/RS), capable of storing 24,750 pallets up to ten deep. Four Westfalia storage and retrieval machines (S/RMs) ensure efficient pallet handling, each processing over 80 pallets per hour with triple-rail support for enhanced safety and reliability.

System Features

AS/RS Footprint: 334,000 sq. ft.

12,000 SKUs

8 million cases

24,750 pallet positions

4 aisles servicing: 10 pallets deep

4 tandem-pallet Satellite® S/RMs in 4 aisles

Pallet conveyor systems

Automatic pallet replenishment to pallet flow pick lanes on 4 levels

Savanna.NET® Warehouse Execution System (WES)

Results

The implementation of Westfalia’s automated warehouse system has significantly increased overall warehouse efficiency, enabling Southern Glazers to manage inventory more effectively and fulfill orders with greater speed and accuracy. The high-density AS/RS has optimized the use of available space, positioning the company for future growth without the need for additional expansion. This advanced system has also improved customer satisfaction by ensuring faster order fulfillment and higher accuracy.