Glenmore Distillery enhanced efficiency and set new benchmarks with state-of-the-art automation…

In today’s fast-paced logistics environment, efficient storage and retrieval are critical for success. Our Automated Storage and Retrieval Systems (AS/RS or ASRS) offer innovative solutions to maximize space, increase efficiency, and improve accuracy in your warehouse operations.

Using a data-driven approach, we ensure our AS/RS solutions are tailored to meet your specific needs.

Backed by decades of expertise and innovative Satellite® technology, Westfalia’s AS/RS solutions ensure consistent performance and minimal downtime. With over 400 installations globally, our experience drives successful outcomes. Our designs of equipment, controls, and software are continually refined with a focus on standardization to ensure long-term support.

Maximize storage capacity by efficiently utilizing vertical and horizontal space. Our AS/RS can store items from 1 deep up to 18 deep on each side of the aisle. It significantly reduces your AS/RS footprint and optimizes space utilization for substantial cost savings. This flexibility supports integrated order selection systems, pass-through routing between aisles, and full “middle block” redundancy.

Westfalia’s AS/RS handles various pallet types and adapts to specific warehouse layouts and operational requirements. It scales easily with your business, accommodating diverse inventory needs and ensuring flexibility and customization.

Our AS/RS solutions ensure smooth, accurate load movements, eliminate deflection and prevent inventory damage. This feature improves system performance and extends operational longevity by providing precise pallet support.

Savanna.NET® Warehouse Execution System (WES) offers real-time inventory tracking, advanced analytics, and seamless integration with the AS/RS. It optimizes material flow and coordinates tasks across subsystems, providing complete control over your operations.

Our AS/RS integrates seamlessly with our advanced warehouse systems, enabling a unified process that eliminates the need for manual intervention. By manufacturing most equipment and developing all software and control systems in-house, we maintain superior quality, control, and reliability.

This vertically integrated approach reduces risks and ensures unmatched quality, leading to cost-effective and timely solutions that are fully supported now and into the future. Our systems can handle a wide variety of products and storage requirements, providing the following benefits:

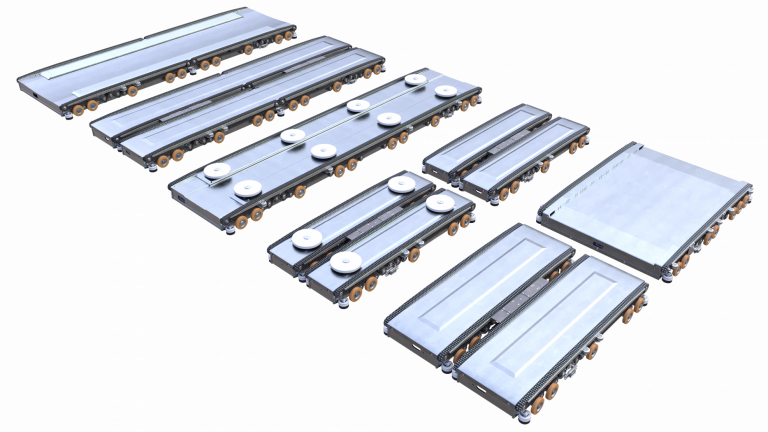

Westfalia’s AS/RS solutions are built on advanced technologies and designed for optimal performance and flexibility in various warehouse configurations.

Our S/RM enables efficient horizontal and vertical positioning movement within your AS/RS, providing versatility across many applications regardless of depth, height, or width constraints.

Westfalia’s Satellite® Rack Entry Vehicle delivers quick, safe, and versatile pallet handling, outperforming traditional rack entry vehicles that lift the load. The design includes a center third rail for proper pallet support and can handle one or two pallets at a time in your AS/RS.

Our Savanna.NET® Warehouse Execution System (WES) serves as the central hub for optimized inventory management and order fulfillment in your warehouse. Seamlessly integrating with conveyors, picking systems, palletizing equipment, and more.

Our systems ensure efficient, continuous, and accurate movement of goods within the AS/RS, enabling seamless operations across diverse warehousing configurations.