Overview

With a rich legacy dating back to 1773, Buffalo Trace Distillery sought to modernize its distribution processes to overcome the limitations of outdated warehouse systems and manual handling. This modernization initiative was pivotal in enhancing productivity, refining operational efficiency, and solidifying Buffalo Trace’s reputation as a leader in bourbon production.

Challenge

Buffalo Trace Distillery faced significant warehousing challenges, including limited storage capacity and inefficient pallet movement. These issues impeded the distillery’s ability to meet FIFO (First In, First Out) objectives during high-product occupancy periods, leading to increased labor costs, higher risk of inventory damage, and operational bottlenecks during peak shipping times. Recognizing these hurdles, the distillery sought an advanced solution to address these operational inefficiencies.

Solution

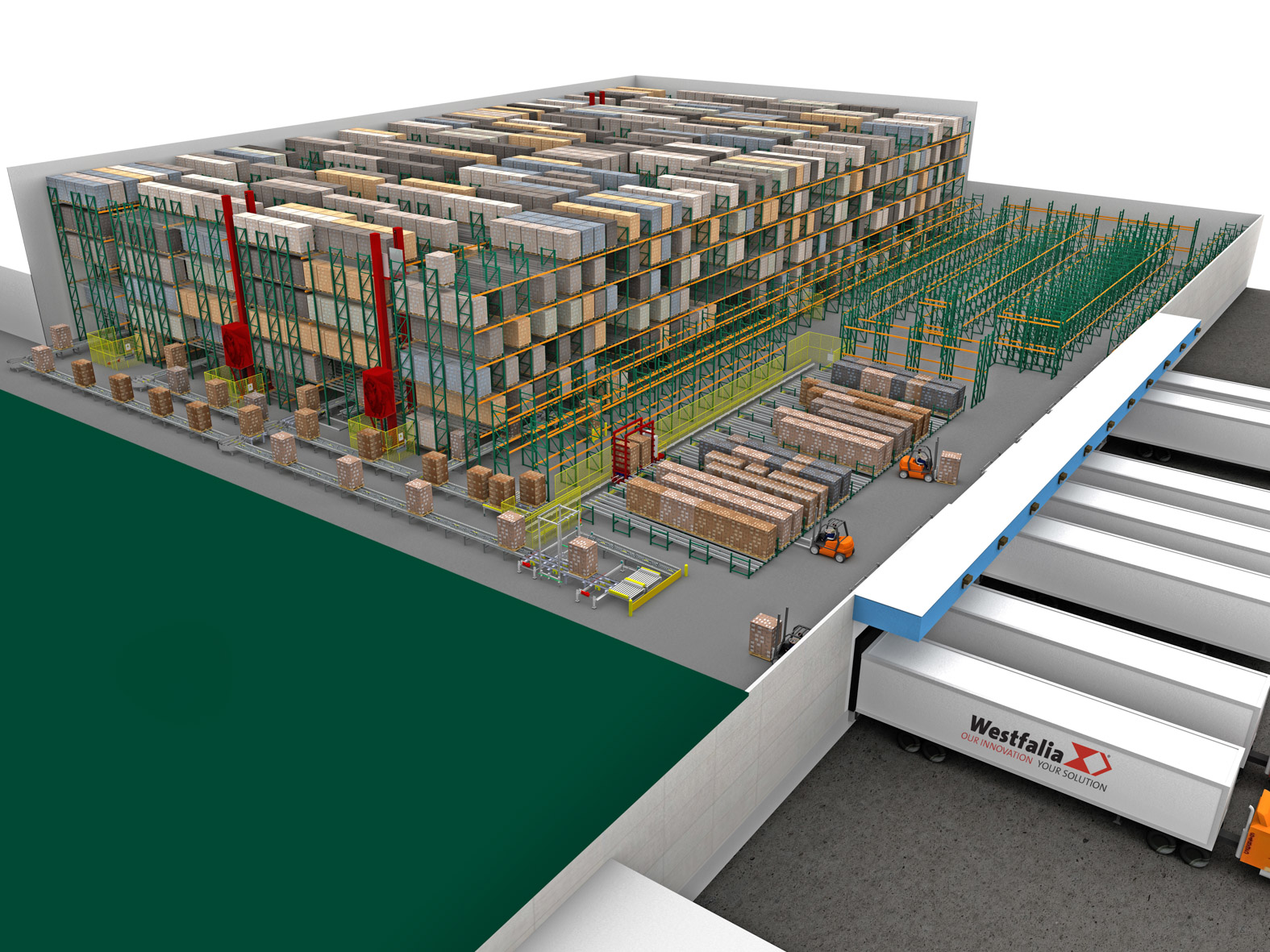

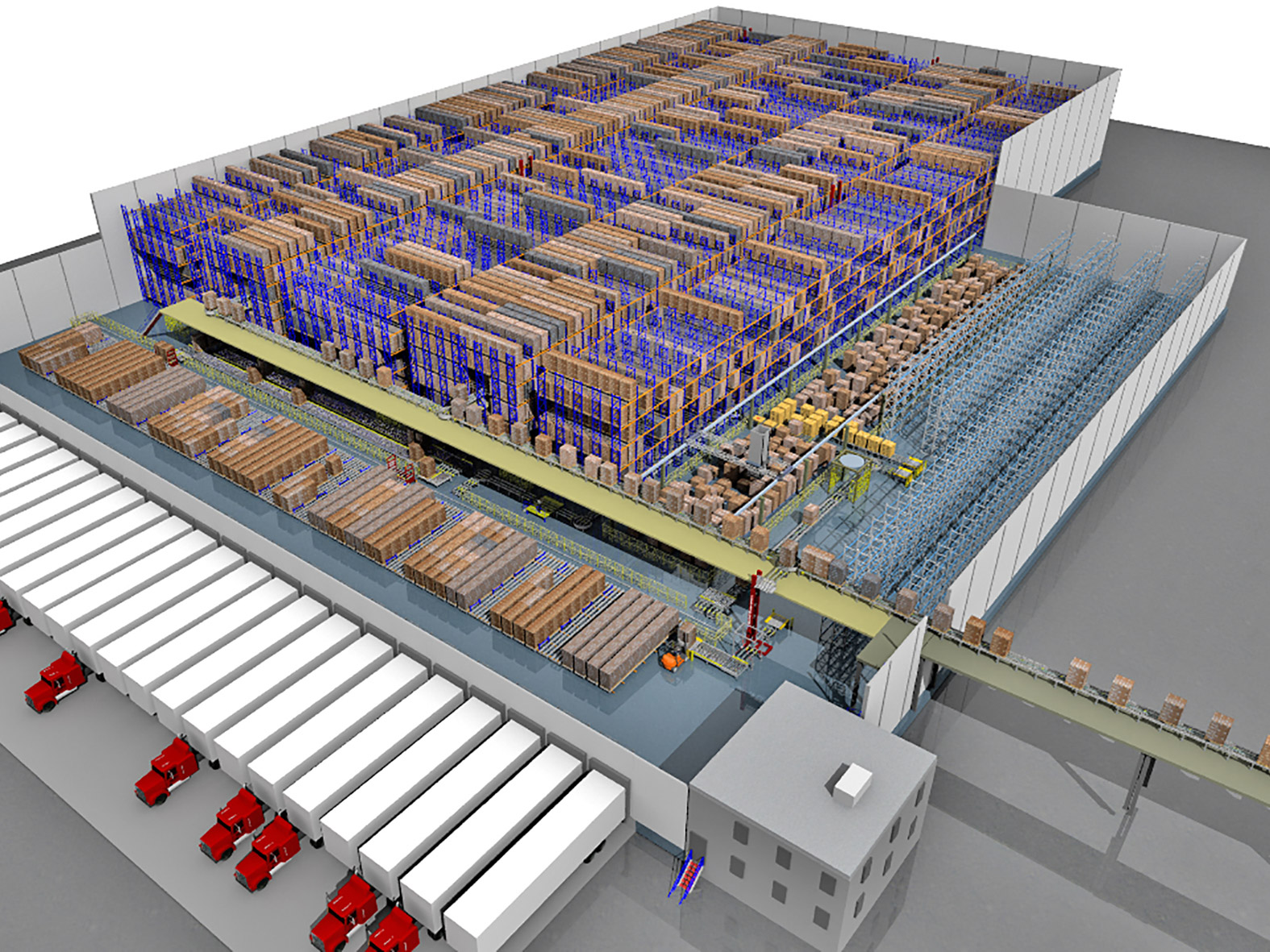

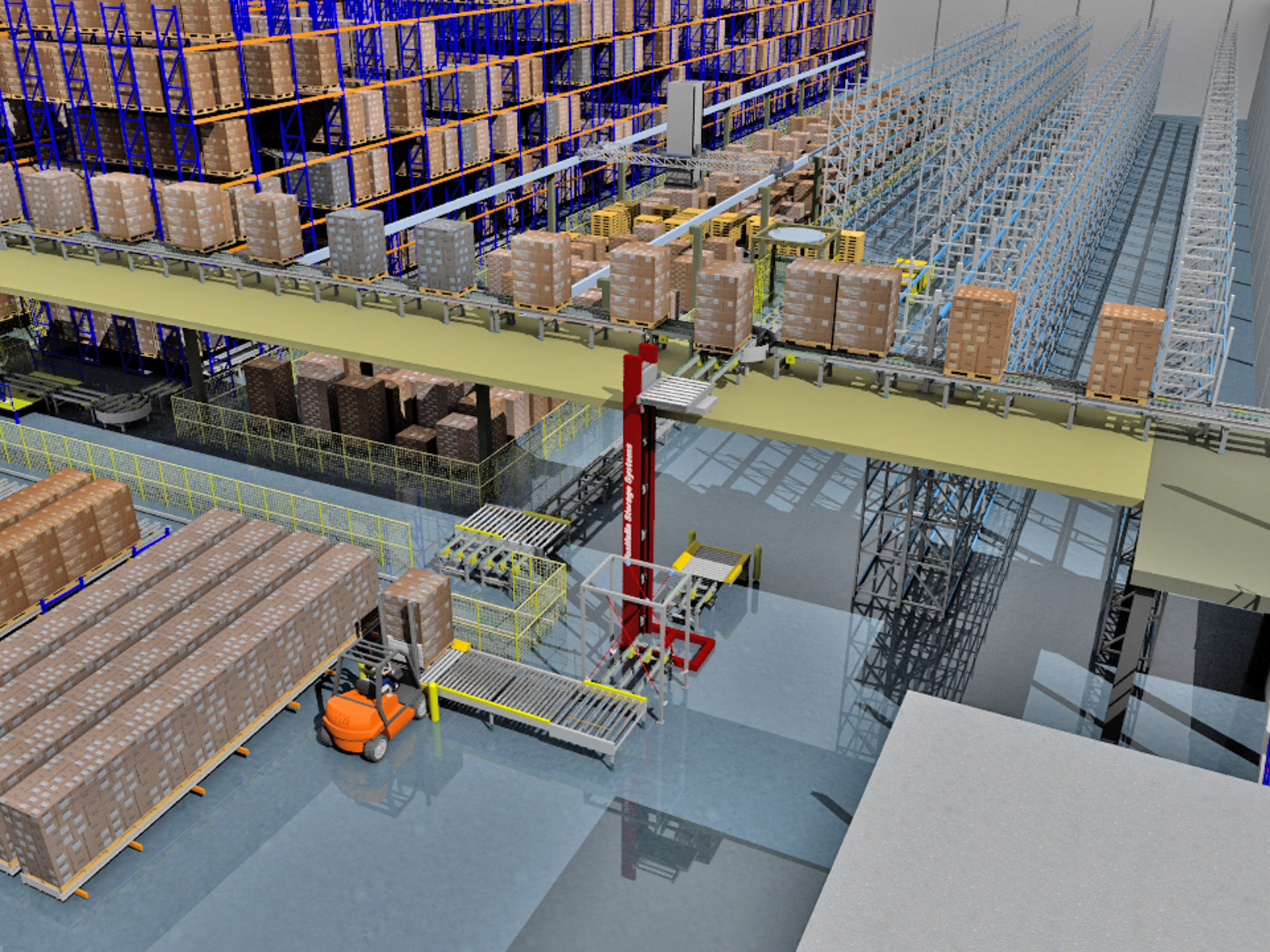

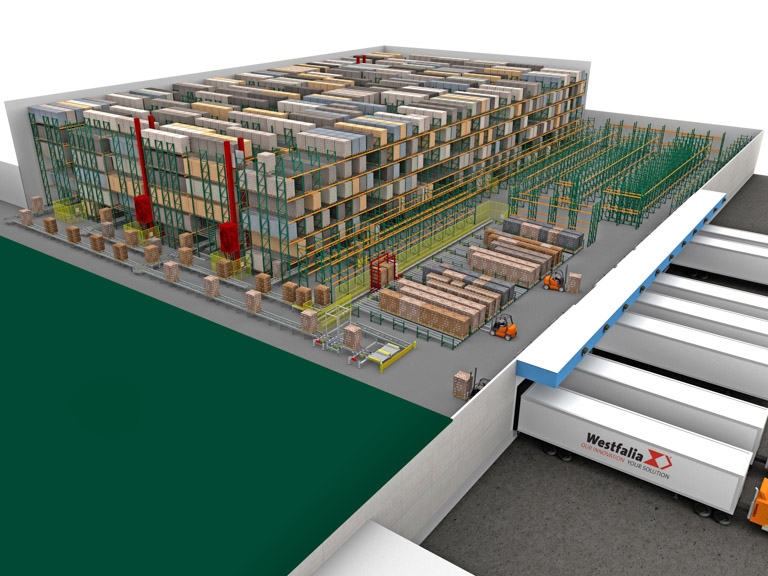

To overcome its operational challenges, Buffalo Trace partnered with Westfalia Technologies to develop a state-of-the-art automated warehousing system. This project included the construction of a new 83,000 square-foot facility, featuring Westfalia’s Automated Storage and Retrieval System (AS/RS) and Savanna.NET® Warehouse Execution System (WES). The technologies provided real-time inventory tracking, optimized material flow, and improved order fulfillment, thereby modernizing the distillery operations, reducing reliance on manual processes, and significantly improving distribution efficiency.

System Features

AS/RS Footprint: 46,654 sq. ft.

Number of aisles: 3

AS/RS Pallet Storage: 10,619 positions

Storage: 5-deep storage lanes x 6-levels high

Outbound Order Staging: 20 lanes x 10-deep, up to 200 pallets

3 Satellite® S/RMs in 3 aisles, 6-levels high

Automated Outbound Order Staging System

Savanna.NET® Warehouse Execution System (WES)

Real-time integration with Buffalo Trace’s ERP system

Results

The implementation of Westfalia’s automated distribution solution marked a significant milestone in operational excellence for Buffalo Trace Distillery. The new AS/RS system achieved notable reductions in labor and equipment needs while centralizing operations. With its sophisticated design, the system maximized storage density, safeguarded product quality, and optimized order fulfillment processes. This transformation has not only improved space utilization and order fulfillment but also strengthened customer trust and affirmed Buffalo Trace’s position as leader in modern distribution.